OUR SERVICES

leaders in technology

Industrial solutions are defined by the precision. Therefore, the technology we offer is above and beyond standard machining. Our self-contained EAGLE Laser technology can beam cut through metal with such intense strength, precision & detail, providing solutions that previously were not able to be manufactured. N.E. REIHART will provide your solutions simply, accurately and on time.

Below is the list of our traditional and Hi-Tech equipment:

METAL FORMING

Safan-Darley E-Brake 35T Premium – 35 ton fully electric press brake, ideal for bending parts 4ft wide and under

Trumpf Tru-Bend 5130X – 147 ton hydraulic press brake with 10ft bending width

Accurpress Accell 425012-E – 250 ton hydraulic press brake with up to 12ft bending capacity

MG M1206P Plate Rolls – 4 Roll CNC with up to ¼” or 4ft wide capacity

Wysong Plate Rolls – 3 Roll mechanical with up to 3/8” or 5ft capacity

Miscellaneous specialty mechanical and hydraulic rolls

Diacro Power Bender, for bending bar stock

Ercolina , Programmable tubing bender for handrails and similar parts

Various manual hydraulic presses for bending, straightening, and flattening

CNC CUTTING

Omax 80X Waterjet – 60,000 PSI waterjet with 6ft x 12ft capacity and 5-axis head for beveling up to 60°

Eagle Inspire 1530 Fiber Laser – 15 kW with 5ft x 10ft table with the ability to cut 1”+ steel and stainless, 1” aluminum and 3/8” copper and brass

Mitsubishi ML3015EX CO2 Laser – 6 kW with 5ft x 10ft table

MANUAL CUTTING

Wysong Shear – 10ft x 3/16” capacity

Hydmech H-14A Bandsaw – automatic horizontal with 14” x 14” capacity

Hydmech S-20 Bandsaws – manual and automatic scissor style

Geka Ironworker, for shearing and punching of bar stock

Deburring, Blasting, and Finishing

(2) Timesaver Lynx sanding machines – for metal finishing and deburring up to 37” wide

Almco SBB-12V round bowl vibrator – for tumbling and deburring small parts

Wheelabrator blast machine – for automated blasting of hanging steel parts

Nonferrous and ferrous blast rooms -media blasting for various materials without cross contamination

Blast-It-All cabinets, Small parts blast cabinets

GFS Paint Booth– 14ft x 32ft room for wet painting of industrial finishes

WELDING

Miller PA750S Robotic welding cell – 2 station robotic welder for high production parts

Arcworld by Motoman Robotic welding cell – 2 station robotic welder for high production parts

Manual MIG, TIG, Stick welders – plus braising and soldering, for repairing and connecting a wide range of metals

Part rotators – for improved manual welding of round parts

MACHINING

Okuma Spaceturn LB3000EX CNC Lathes Okuma Spaceturn LB3000EX CNC Lathes – for production runs of turned parts, (2) have the ability to perform mill type work via A Z-Axis and Live Tooling

Okuma Spaceturn LB3000EX CNC Lathes – for production runs of turned parts, (2) have the ability to perform mill type work via A Z-Axis and Live Tooling

Lathes

ProtoTRAK TRL 2460SX Lathe – Manual/automatic control options with 24” swing and 4” spindle through hole

Manual lathes – (6) options for up to 36” diameter and 12ft long

Mills

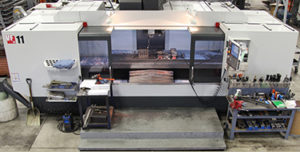

Haas VF Series machining centers, VF-2SSYT, VF-4SS, VF5-SS, and (our biggest) a VF-11 with 40” x 120” of travel with a 4th Axis (rotary option)

Haas UMC-750 – 5-Axis mill with 30” x 20” x 20” working envelope

ProtoTRAK DPM3 Mill – Manual/automatic control options

Bridgeport Mills – 3 manual

Hansford-Davis Keyseater – for manual cutting of keyways

Your project includes critical specifications

Our manufacturing process follows strict guidelines to deliver each piece as precisely as required. Pre-production planning, project management and quality control procedures are practiced – ensuring your project is completed accurately. We operate precision CNC and manual machine tools better than anyone – including milling machines and lathes – by working directly with you. Using a supplied blueprint or designer’s specifications, N. E. REIHART steps confidently into the process of making your parts and machines with exactness and fine attention to detail.

TIMING IS EVERYTHING

Precisely what you need. When you need it.

Anyone in business knows timing is everything. N.E. REIHART understands you need solutions fast. That’s why we stock a wide range of plate, sheet, and structural materials in carbon steel, stainless steel, and aluminum, but we often have other materials on hand as well.

Your schedule is ours

Receiving what you need, when you need it, is our priority. Internal communication through every step of the manufacturing process will deliver your project precisely when you need it.

BRING YOUR IDEAS TO US!

You have a job to do and we want to make it easy for you!

Our customers repeatedly rank us among the best resources they work with. This is no accident. You can depend on N. E. REIHART. We service ANYONE that makes something. If your Industry makes a product, chances are that you will need a NEW or REPAIRED PART or a COMPLETE MACHINE or related services inside your company, manufacturing industry or business.